|

Description of electroplating water chiller:

Electroplating water chillers originated in the United States. In the 1960s and 1970s, the United States took the lead in developing water chillers, with the English name Air cool Chiller, abbreviated as Chiller. Electroplating water chillers are commonly known as refrigerators, refrigerators, water chillers, water chillers, and chillers. Due to their wide use in various industries, their names are countless. The principle of its nature is a multifunctional machine that removes liquid vapor through a compression or heat absorption refrigeration cycle. The steam compression chiller consists of four main components: a steam compression refrigeration cycle compressor, an evaporator, a condenser, and some metering devices to achieve different refrigerants. Absorption chillers use water as a refrigerant and rely on the water and lithium bromide solution between them to achieve a strong affinity for refrigeration.

Features of electroplating water chiller:

1、Free cooling tower, easy to install, easy to move, suitable for situations where water sources are lacking;

2、Low noise fan motor, excellent cooling and condensation effect, stable throttle mechanism, excellent rust prevention treatment;

3、Upgrade the heat exchanger made of titanium material to meet the corrosion requirements of the electroplating industry;

4、Adding a corrosion resistant evaporator, stainless steel pipe, stainless steel pump, or using a plate type exchanger can help stabilize metal ions and quickly attach metal ions to the plated parts, not only increasing density and smoothness, but also reducing the number of electroplating times, improving productivity, helping to quickly recover various chemicals, and reducing waste;

5、Upgrade the water tank made of pure stainless steel without coils, with a lasting and stable cooling effect, and a temperature control accuracy of ± 1 ℃;

6、Add ultra-high and low temperature display and signal output protection, and configure normally open and normally closed outputs for selection;

7、The upgraded chilled water circulation system uses stainless steel multi-stage pumps and stainless steel, connected with PVC material, without the worry of corrosion, and can directly use purified or deionized water;

8、Add a water filter to provide the precision of high-quality laser operation, add a water outlet pressure display meter to facilitate the adjustment of pressure and flow, add a flow protection device, automatically disconnect the laser power supply when the water flow is too low, prevent the laser head from overheating due to lack of water, add electronic temperature control, dual digit display, and have multiple settings and fault display functions, with only one button operation (key on), and other functions are automatically realized by memory function;

9、The refrigeration capacity ranges from 102500 Kcal/h to 654800 Kcal/h.

10、The unit does not need to be equipped with auxiliary equipment such as cooling water pumps and cooling towers. It can be used as long as it is in a well ventilated place, which can greatly save materials and engineering installation costs, and even does not require the establishment of a computer room.

11、In addition to approved products, our company can also customize various special water chillers and heat pump units according to customer requirements, and provide on-site assembly, technical guidance, and on-site commissioning services.

12、The condenser of the unit is of the finned type, made of double oil corrugated hydrophilic aluminum platinum, and manufactured by professional heat exchanger processing equipment. It has the advantages of compact structure, small size, light weight, and high heat exchange efficiency. It is equipped with a large blade axial flow fan with low rotational speed, which can effectively reduce operating noise and reduce the impact on the surrounding environment.

Working principle of electroplating water chiller Installation steps of electroplating water chiller:

Installation steps of electroplating water chiller:

1、The site for installing the unit must be a floor, mounting pad, or foundation, with a levelness within 6.4 mm, and be able to withstand the operating weight of the unit.

2、Select water pipes with appropriate pipe diameters, cooling systems and cold water systems when the unit is operating at maximum power, and connect them correctly.

3、At one end of the unit, a space for cleaning the condenser tube bundle should be reserved, and door openings or other openings at suitable locations can also be used.

Installation precautions:

1、In order to reduce noise and vibration, it is best to install vibration isolators on the pipes.

2、Generally speaking, proper water treatment and regular cleaning of the tube bundle can maintain its good performance. If the existing water quality conditions cannot be improved by appropriate methods, it is necessary to consider allowing the tube bundle to have a larger fouling coefficient or specifying special structural materials.

3、The unit should be placed in a machine room with a room temperature of 4.4-43.3 ℃, and there should be sufficient space around and above the unit for daily maintenance work.

Scope of application:

Use occasions of water chillers: mold cooling in the plastic industry, electroplating pool cooling in the electroplating industry, various cooling in the electronic industry, various cooling in the chemical industry, various cooling in the pharmaceutical industry, cooling in the food industry, constant temperature cooling in the preservation industry, and cooling by various air conditioning equipment.

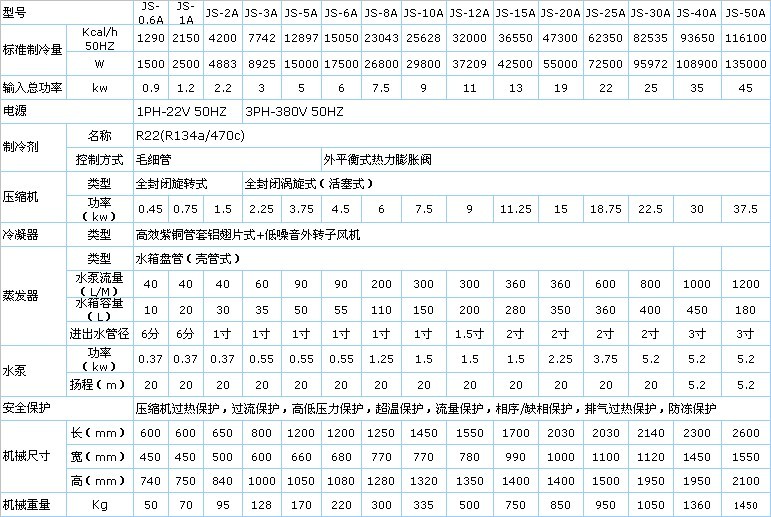

Technical parameter:

Note: The above products are continuously improved and innovated, and the specifications are subject to change without further notice. Please forgive me, and we can customize the models according to customer requirements.

|