|

| Dehumidification dryerPRODUCTS |

|

|

Name:Dehumidification drying feed combination

Model:

|

|

| Details: |

Europeanchem dehumidification drying and feeding combination (three machines in one))

main features:

1、The dehumidification, drying, and feeding combinations are all equipped with a honeycomb rotary dehumidifier, which is divided into two types: closed type and semi open type.

2、It integrates dehumidification, drying, and two-stage feeding functions, and can optionally purchase three-stage feeding functions.

3、The replacement cost of the runner is low, durable, and has a long service life.

4、The fully stainless steel double-layer thermal insulation drying barrel adopts a downdraft design, coupled with a cyclone exhaust device, to prevent heat loss, ensure temperature, and improve drying efficiency.

5、This machine is equipped with microcomputer control as a standard equipment, with optional PLC control and LCD touch type human-machine interface, which is centralized and convenient for operation, and can control the automatic operation of the entire machine.

6、The closed loop feeding system can prevent the dried raw material from moisture regain due to contact with external air.

7、Intermittent air conveying cleaning can not only supply the molding machine with an appropriate amount of material, but also ensure that there is no residue left in the conveying supporting pipe.

8、The use of valveless air shutoff eliminates undesirable phenomena such as material sticking and foreign matter mixing that can easily be caused by control methods such as using valves.

9、The machine occupies a small area and is easy to move. It can be replaced at will.

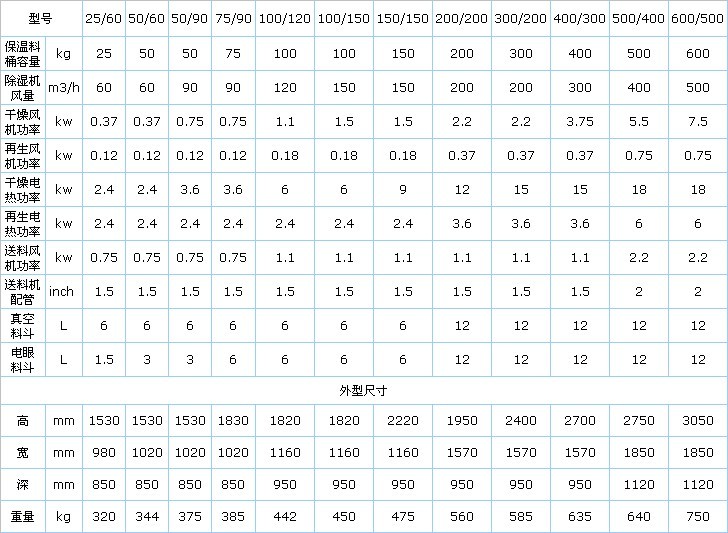

technical parameter >

Note: The above products are continuously improved and innovated, and the specifications are subject to change without further notice. Please forgive me, and we can customize the models according to customer requirements. |

|